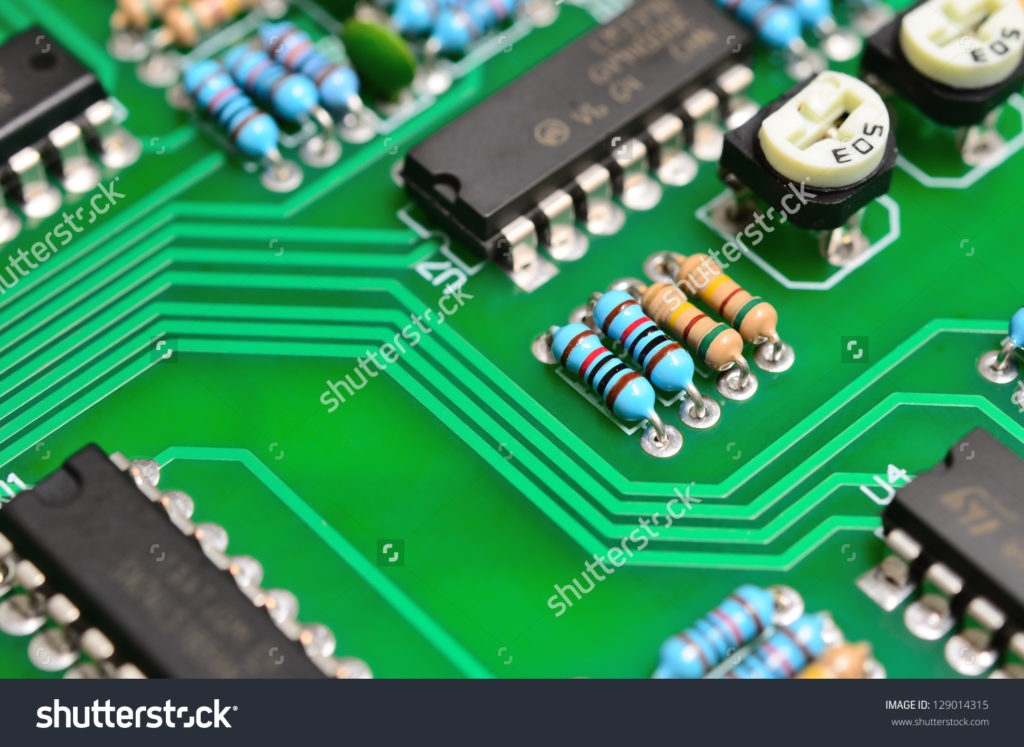

The PCB has been at the core of everything we do since our founding. Our business naturally evolved from selling PCBs to also include the next stage, populated boards in completed products. As a value-added service to our customers, ISM conducts DFM/technical review seminars: day-long, face-to-face educational sessions in which our PCB experts meet with the customer’s design and engineering teams to review the technical specifications of their project. We listen to our customers’ unique needs and recommend optimized design solutions. In addition to reviewing such areas as base materials, copper requirements, and PCB design in general, we break down each element to truly understand such aspects as surface finish, solder mask color, impedance requirements, optimal board size, and others. We help customers strike a balance to design better-performing boards that are easier to manufacture, reducing costs and improving internal processes.

Bare Printed Circuit Boards (PCB), Assemblies (PCBA), and Finished Goods Production

PCB Capabilities:

- Manufacturing sites in China and Thailand

- ISO9001:2008, ISO14001:2004, and ISO/TS16949:2009 certified

- Capacity: > 6 million square feet per month

- Prototype through high volume production

- Layer count: 2-20

- HDI: 1+4+1, 1+6+1, 2+4+2, 2+6+2

- VIP technology

- Laminates: CEM-3, FR-4, High Tg FR-4, Halogen-Free, High CTI/Low Dk

- Copper Thickness: 0.5 oz. – 4.0 oz.

- Minimum line/spacing: 3mil / 3mil

- Surface finishes: HASL, Lead-free HASL, OSP, Immersion Silver, Immersion Tin, ENIG, Carbon Ink, Peelable solder mask

- Board Thickness: .012″ – .125″

PCBA Capabilities:

- 9 global manufacturing/production sites across Thailand, Philippines, Brazil, Mexico, USA and China

- 10 global research and development sites

- 2 software development sites

- Quality standards: ISO 9001, ISO 14001, OHSAS 18001, Sony GP, QC080000, TL-9000, TS16949, QS9000, ISO 13485

- Safety certifications: UL, TUV, BEAB, JQA, CSA, EMC, CCC – PCBA, Low volume -Hi mix to High Volume – Low mix, SM/PTH/full system assembly

- Full test capabilities including SPI, AOI, X-Ray, ICT, Function Testing and Burn-in/ORT.

- In-House Test Development capability

- In- house Factory Automation group

- plastic injection molding

- metal stamping

- powder sintering

- die casting

- aluminum extrusion

- rubber parts molding

- jig, fixture, and tester design and fabrication

- bar code and RFID product tracking management system